Latest News

State-of-the-art satellite test facility in the UK.

UPDATE: Up and Running in 2024 The National Satellite Test ...

Read More →

Sierra Space’s Dream Chaser to Undergo Vibration Testing

Testing is scheduled to start in mid-to-late December. Dream Chaser ...

Read More →

Join Us at Space Tech Expo Europe

November 14-16, 2023 | Bremen, Germany Experts from NVT Group ...

Read More →

Join us at the 93rd SAVE Symposium

SEPTEMBER 24-28, 2023 | ATLANTA, GA Experts from Team Corporation ...

Read More →

Join us at the Aerospace Test & Development Show

September 19-20 – Toulouse, France Experts from Team Corporation and ...

Read More →

Join Us at ESTECH 2023

May 8-10, 2023 | Minneapolis, Minnesota Experts from Team Corporation ...

Read More →

Join Us at Space Tech Expo USA

May 2-4, 2023 | Long Beach, California Experts from Team ...

Read More →

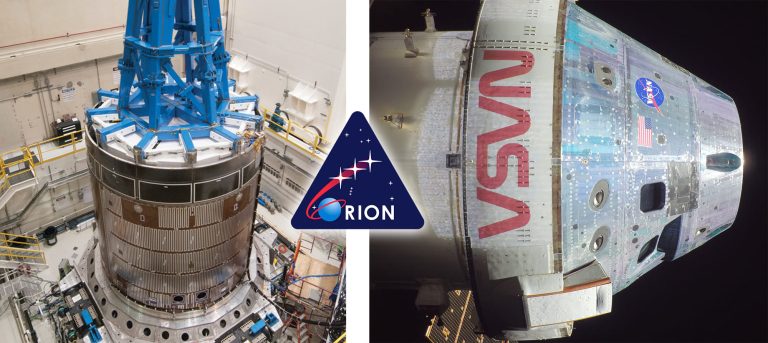

NASA’s Orion: From 2016 Testing to the 2022 Launch

2022: Orion’s First Flight! Following a successful launch of NASA’s ...

Read More →